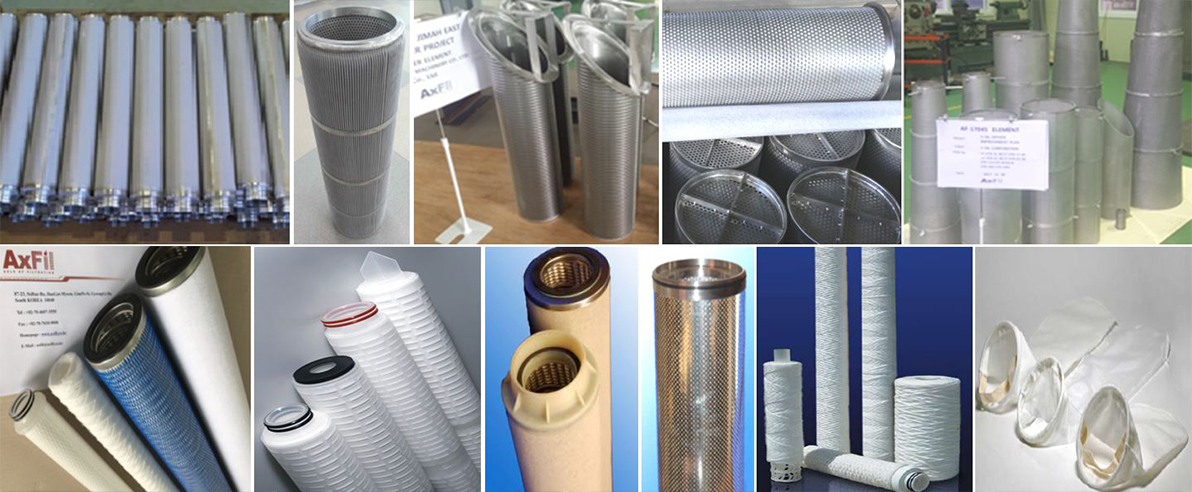

Elements are selected depending on which substance the filter is using.

Basic design of the filters are mostly decided by the element.

So it is very important to know the appropriate element to use.

Powder Sintered Media

Porous media is produced by diffusion sintered bond of powder metal

Features

- Porousness uniforms as it becomes sintered form with regular particle.

- Filtration efficiency is high because it is depth type to pile up pollution material in the twisted windingly flow passage.

- Durability and conservation capacity for filtration particle of medium is excellent as it is formed by the sintered method of powder metal.

- It can be used variously as it is produced by various material, SS 304L, 316L, INCONEL600, Semi-permanent and regeneration effect is

high with reverse-cleaning and supersonic cleaning method as the washing rate is excellent with high washing rate.

- The application limit of temperature is wide range from super-low-temperature to high-temperature of 926℃.

- Can endure the high-pressure-drop and can be applied to high pressure as it has high burst and collapse pressure.

- Possible to apply Auto Filtration System of Catalyst Recovery at the base of the above detailed excellent features.

Powder Sintered Medium

- Liquid Rating : 2 microns absolute

- Porosity : 35%

- Flow (H2O) : 2 gpm/ft² at 0.5 psid

- Contaminant Capacity : 0.7 g/ft² at 0.5 psid

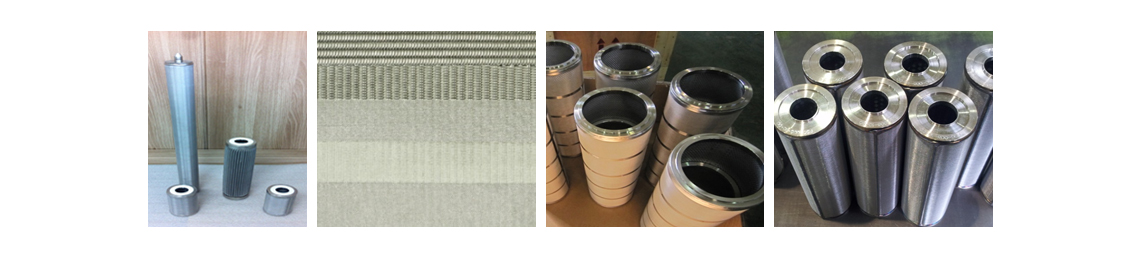

Multi-Layer Sintered Media

This media is produced through Multi-Layer Diffusion Sintered Bond of Woven Wire Screen to be woven by metal wire in order of support layer, distribution layer, filtration layer and protection layer.

Features

- It is a metal net weaved at regular intervals and maintains the uniform pore, as it becomes sintered forming.

- The choice range of filtration granularity is wide.

- Media production is possible as it adjusts join order of metal net according to usage.

- Treatment is easy and supporting or reinforcing structure isn’t required as it is solid.

- Advantageous in high-temperature and corrosion applications as it is made by high resistant raw materials such as SS 304, 304L, 316,

316L.

- Can endure a high-pressure-drop and advantageous to high-pressure as it has high-burst and collapse pressure.

- Semi-permanent and regeneration effect is

high with super-sonic wash or reverse-wash.

Woven Wire Cloth Laminate

- Liquid Rating : 2 microns absolute

- Porosity : 35%

- Flow (H2O) : 2 gpm/ft² at 0.5 psid

- Contaminant Capacity : 0.7 gms/ft² at 0.5 psid

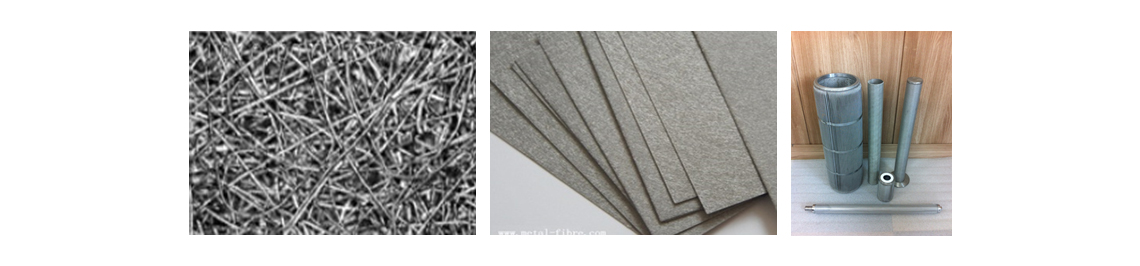

Fiber Metal Sintered Media

This media is produced by Diffusional Sintered Bond with mat type of fiber metal media.

Features

- Filtration effect is high as fiber metal media type is sintered.

- Conservation ability of filtration particle is excellent.

- The pressure loss is low as the media is very delicate and permeability is very high.

- Large heaping capacity for pollution material sustains long life span.

- Pleated type cartridge can be produced.

- High range of application for fluid and gas and corrosion resistance is excellent as it is possible to produce by various materials such as

SS316L, INCONEL 601, FECRALLOY, HASTELLOY X and etc.

- Semi-permanent and regeneration effect is high with super-sonic wash or reverse-wash as permeability is high and wash is excellent.

Fiber Metal Medium

- Liquid Rating : 2 microns absolute

- Porosity : 60%

- Flow (H2O) : 8 gpm/ft² at 0.5 psid

- Contaminant Capacity : 2.2 gms/ft² at 0.5 psid

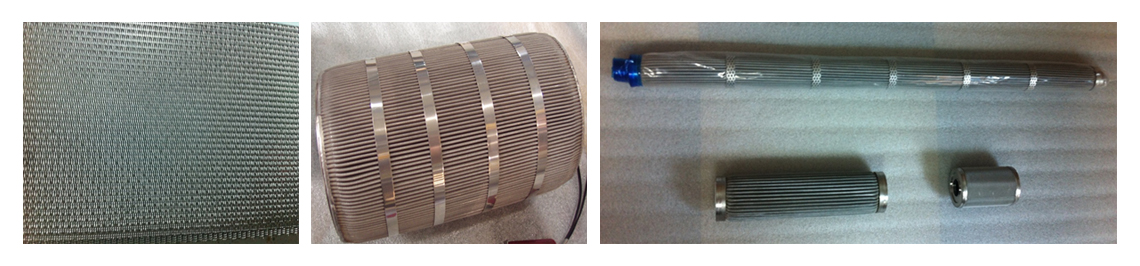

Woven Wire Screen Media

Woven wire screen depends on the weaving method having different merits by each various figures.

Features

- Cartridge for Woven Wire Screen is produced by Mono-Layer Metal Screen or Multi-Layer Metal Screen welded with several layers of

support layer, distribution layer, filtration layer and protection layer depending on the usage.

- Possible to produce by meeting order of metal screen depending on the usage.

- Can be applied to high-temperature, high-pressure and corrosion resistance is excellent as it is made by raw materials such as SS 304,

304L, 316, 316L.